Table of Contents

- Designing a Mold for Plastic Injection

- Step 1: Determine the Part Design

- Step 2: Design the Mold Base

- Step 3: Design the Cooling System

- Step 4: Design the Ejection System

- Step 5: Choose the Material for the Mold

- Step 6: Create the Mold Design

- Step 7: Test the Mold Design

- Step 8: Manufacture the Mold

- Step 9: Set Up the Injection Molding Machine

- Step 10: Produce Plastic Parts

- Frequently Asked Questions

- What are the factors to consider when designing a mold for plastic injection?

- What are the different types of mold designs for plastic injection?

- How is the mold designed for plastic injection?

- What are the common defects in plastic injection molding?

- What are the benefits of using computer-aided design and manufacturing for mold design?

Are you looking to design a mold for plastic injection? This may seem like a daunting task, but with the right knowledge and tools, you can create a high-quality mold that produces consistent results.

In this article, we will guide you through the process of designing a mold for plastic injection. From choosing the right materials to considering the various design factors, we will cover everything you need to know to create a successful mold. So, let’s dive in and explore the world of mold design!

- Start by determining the type of plastic you will be using and the shape of the final product.

- Design the mold with the appropriate cavities, gates, runners, and vents.

- Consider the mold’s material, size, and cooling system to ensure proper molding.

- Create a 3D model of the mold and simulate the injection molding process to identify any potential issues.

- Test the mold with a small production run before final adjustments and mass production.

Designing a Mold for Plastic Injection

Designing a mold for plastic injection is a crucial process in the manufacturing of plastic products. It involves the creation of a mold that will be used to produce plastic parts in large quantities. A well-designed mold ensures that the plastic parts produced are of high quality and meet the required standards. In this article, we will cover the basics of designing a mold for plastic injection.

Step 1: Determine the Part Design

The first step in designing a mold for plastic injection is to determine the part design. The part design will dictate the shape and size of the mold. It is important to ensure that the part design is optimized for plastic injection molding. This means that the part should have uniform wall thickness, minimal undercuts, and the appropriate draft angle.

Once the part design has been finalized, it is important to create a 3D model of the part. This can be done using CAD software. The 3D model will be used to create the mold design.

Step 2: Design the Mold Base

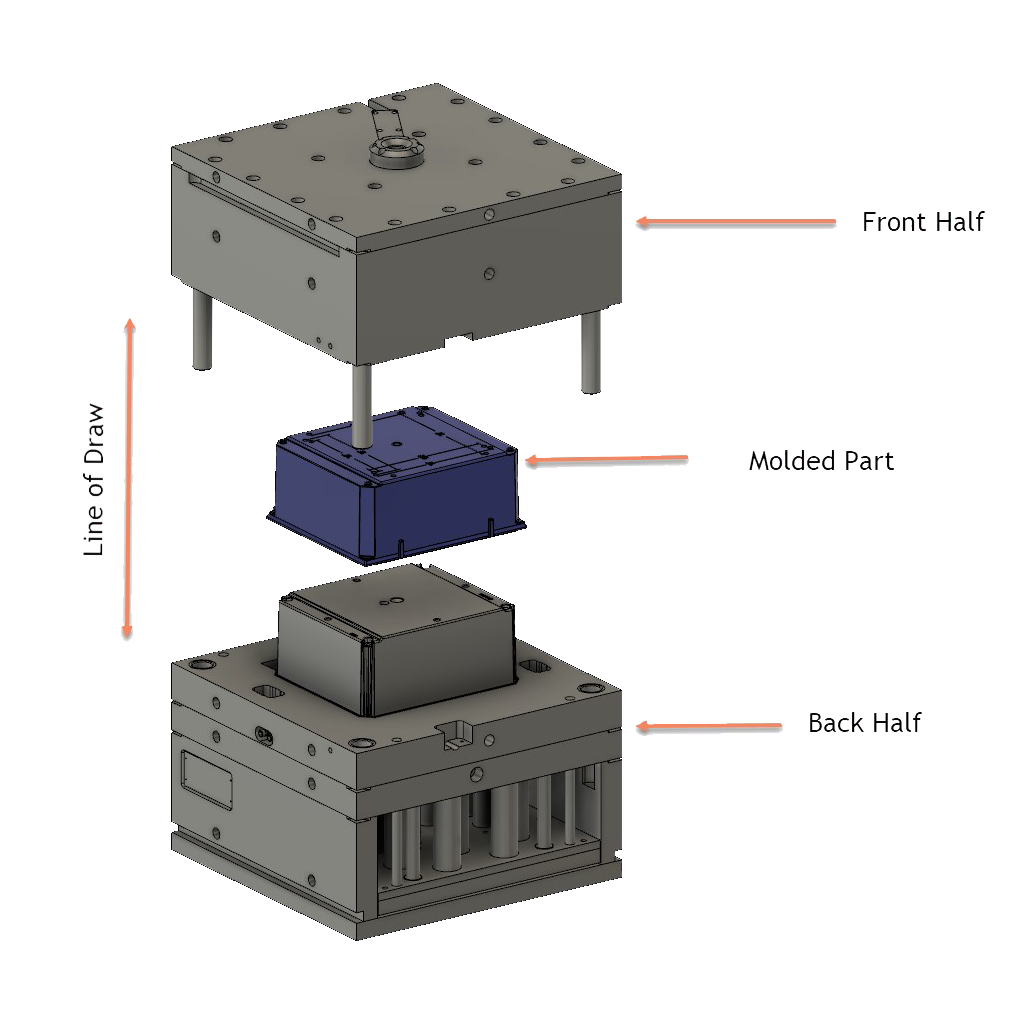

The mold base is the foundation of the mold. It consists of the mold cavity and the mold core. The mold cavity is the part of the mold that creates the shape of the plastic part. The mold core is the part of the mold that creates the holes or cutouts in the plastic part.

The mold base should be designed to withstand the high pressure and temperature of the plastic injection molding process. It should also be designed to allow for easy assembly and disassembly of the mold.

Step 3: Design the Cooling System

The cooling system is an important part of the mold design. It is responsible for controlling the temperature of the mold during the plastic injection molding process. A well-designed cooling system ensures that the plastic parts produced are of high quality and have consistent dimensions.

The cooling system should be designed to allow for even distribution of cooling throughout the mold. This can be achieved by designing the cooling channels to follow the shape of the mold cavity and core.

Step 4: Design the Ejection System

The ejection system is responsible for ejecting the plastic part from the mold after it has been formed. The ejection system should be designed to ensure that the plastic part is ejected without any damage.

The ejection system can be designed in a number of ways, including ejector pins, ejector blades, or hydraulic ejection systems. The design of the ejection system will depend on the size and shape of the plastic part being produced.

Step 5: Choose the Material for the Mold

The material used to make the mold is an important consideration. The mold material should be able to withstand the high pressure and temperature of the plastic injection molding process. It should also be able to maintain its shape and dimensions over time.

Common materials used for molds include steel, aluminum, and copper alloys. Each material has its own advantages and disadvantages, and the choice of material will depend on the specific requirements of the mold.

Step 6: Create the Mold Design

Once all the individual components of the mold have been designed, it is time to create the mold design. The mold design will bring together all the individual components and ensure that they work together seamlessly.

The mold design should be created using CAD software. The software will allow for easy manipulation of the individual components and will ensure that the mold design is accurate and precise.

Step 7: Test the Mold Design

Before the mold is manufactured, it is important to test the mold design. This can be done using simulation software. The simulation software will allow for the testing of different molding conditions and will ensure that the mold design is optimized for the plastic injection molding process.

Step 8: Manufacture the Mold

Once the mold design has been finalized and tested, it is time to manufacture the mold. The mold can be manufactured using a variety of techniques, including CNC machining, EDM, or casting.

The manufacturing process should be closely monitored to ensure that the mold is manufactured to the required specifications. Once the mold has been manufactured, it should be inspected to ensure that it meets the required standards.

Step 9: Set Up the Injection Molding Machine

Once the mold has been manufactured, it is time to set up the injection molding machine. The injection molding machine should be set up to ensure that the plastic injection molding process is optimized for the specific mold.

This involves setting the appropriate temperature, pressure, and speed settings for the injection molding machine. It is important to ensure that the injection molding machine is calibrated correctly to ensure that the plastic parts produced are of high quality.

Step 10: Produce Plastic Parts

Once the injection molding machine has been set up, it is time to produce plastic parts. The plastic parts should be produced in accordance with the required specifications.

The plastic parts should be inspected to ensure that they meet the required standards. Any defects or issues should be addressed immediately to ensure that the plastic parts produced are of high quality.

Conclusion

Designing a mold for plastic injection is a complex process that requires careful planning and attention to detail. By following the steps outlined in this article, you can ensure that your mold design is optimized for the plastic injection molding process and produces high-quality plastic parts. A well-designed mold can save time and money, and ensure that your plastic parts meet the required standards.

Frequently Asked Questions

Here are some commonly asked questions about designing a mold for plastic injection.

What are the factors to consider when designing a mold for plastic injection?

When designing a mold for plastic injection, there are several factors to consider. Firstly, you need to consider the type of plastic material that will be used. Different materials have different melting points and require different mold temperatures. Secondly, you need to consider the shape and size of the part that will be produced. This will determine the number of cavities needed in the mold. Thirdly, you need to consider the injection molding machine that will be used. The mold design must be compatible with the machine. Finally, you need to consider the cost of the mold. The more complex the mold, the more expensive it will be.

The design of the mold is critical to the success of the injection molding process. A well-designed mold can produce high-quality parts consistently and efficiently.

What are the different types of mold designs for plastic injection?

There are several types of mold designs for plastic injection. The most common type is the two-plate mold, which consists of a cavity plate and a core plate. The plastic material is injected into the cavity and solidifies to form the part. Another type of mold is the three-plate mold, which has an additional plate for separating the runner and gate from the part. A hot runner mold is another type, which uses a heated runner system to keep the plastic material in a molten state. Finally, there is the stack mold, which has multiple parting lines and can produce multiple parts in one shot.

The choice of mold design depends on several factors, such as the size and shape of the part, the number of parts required, and the type of plastic material used.

How is the mold designed for plastic injection?

The mold design process involves several steps. Firstly, the part design is analyzed to determine the best mold design for the part. This involves considering factors such as the part size, shape, and material. Secondly, the mold is designed using computer-aided design (CAD) software. The mold design includes details such as the number of cavities, the parting line, and the gating system. Thirdly, the mold is manufactured using computer-aided manufacturing (CAM) software, which generates the tool paths for the CNC machines that will make the mold. Finally, the mold is tested and refined to ensure that it produces high-quality parts.

The mold design process requires a high level of expertise and attention to detail. A well-designed mold can produce parts with high precision and consistency.

What are the common defects in plastic injection molding?

There are several common defects that can occur in plastic injection molding. One of the most common defects is warping, which occurs when the part cools and shrinks unevenly. Another common defect is sink marks, which occur when the plastic material sinks inwards due to insufficient cooling or packing pressure. Flash is another common defect, which occurs when excess plastic material escapes from the mold. Finally, there are short shots, which occur when the mold does not fill completely.

To prevent these defects, it is important to design the mold correctly and to optimize the injection molding process. This involves adjusting parameters such as the injection pressure, temperature, and cooling time.

What are the benefits of using computer-aided design and manufacturing for mold design?

Computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies offer several benefits for mold design. Firstly, these technologies allow for faster and more accurate design iterations. Changes can be made quickly and easily, without the need for physical prototypes. Secondly, these technologies allow for more complex and precise mold designs. Thirdly, these technologies can help to optimize the injection molding process, by simulating the flow of plastic material and identifying potential defects. Finally, these technologies can help to reduce the cost of mold design and manufacturing, by minimizing the need for manual labor and reducing waste.

Overall, computer-aided design and manufacturing are essential tools for modern mold design and injection molding.

In conclusion, designing a mold for plastic injection is a crucial process that requires attention to detail and precision. By following the necessary steps and guidelines, you can create a mold that will produce high-quality plastic parts and help your business thrive.

Remember to consider factors such as the material choice, part design, and mold construction when designing the mold. Additionally, working with a team of experienced professionals can help you achieve optimal results and avoid common pitfalls.

With the right approach and mindset, you can create a mold that meets your specific needs and exceeds your expectations. So, take the time to plan and execute your mold design carefully, and enjoy the benefits of efficient and effective plastic injection molding.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com