Table of Contents

- How to Improve Sand Casting Surface Finish?

- Frequently Asked Questions

- What factors affect the surface finish of sand castings?

- What are some common surface defects in sand castings?

- How can mold coatings improve the surface finish of sand castings?

- What role does post-casting surface treatment play in improving sand casting surface finish?

- How can quality control measures help improve sand casting surface finish?

Sand casting is a popular manufacturing process that involves the creation of complex metal components by pouring molten metal into a sand mold. However, achieving a high-quality surface finish can be challenging, as the sand mold can create rough textures and other imperfections on the final product. In this article, we will discuss some effective techniques for improving the surface finish of sand castings, including mold preparation, gating design, and finishing processes. By following these tips, you can enhance the appearance and functionality of your sand casted components, making them more suitable for your intended applications.

- Use high-quality sand with the right grain size and shape.

- Keep the sand clean and free of debris.

- Use a mold release agent to prevent the sand from sticking to the pattern.

- Control the temperature and humidity in the molding area.

- Optimize the pouring temperature and speed to prevent defects.

- Use a vibrating table to compact the sand and improve the surface finish.

By following these steps, you can improve the surface finish of your sand castings and ensure a high-quality end product.

How to Improve Sand Casting Surface Finish?

Learn the top techniques to improve the quality of sand casting surface finish and take your casting results to the next level.

Use High-Quality Sand

One of the most important factors in achieving a high-quality surface finish is the type of sand used. Choose a high-quality sand that has consistent grains and does not contain any impurities. The sand should also be well-rounded and have a low clay content. When using a new batch of sand, it is important to test it for compatibility with the casting material and to ensure that it does not contain any contaminants.

Using high-quality sand will result in a smoother surface finish and reduce the amount of surface defects such as roughness, pits, and scratches. It will also help to improve the dimensional accuracy of the finished casting.

Control the Moisture Content of the Sand

The moisture content of the sand has a significant impact on the surface finish of the casting. Too much moisture can result in a rough and uneven surface, while too little moisture can cause the sand to break apart during the molding process. It is important to maintain a consistent moisture content throughout the sand mixture to ensure a smooth surface finish.

Using a moisture meter can help to accurately measure the moisture content of the sand. The ideal moisture content will vary depending on the type of sand and casting material being used, but generally, a moisture content of around 2-3% is recommended.

Use the Right Molding Techniques

The molding technique used can also have a significant impact on the surface finish of the casting. Improper molding techniques can result in surface defects such as cracks, roughness, and misalignment. It is important to use the correct molding techniques for the specific casting material being used.

One effective technique is to use a high-pressure molding process, which can help to produce a smoother surface finish and reduce the occurrence of surface defects. Additionally, using a vacuum molding process can help to eliminate air pockets in the sand mixture, resulting in a more uniform surface finish.

Control the Pouring Temperature

The pouring temperature of the casting material can also affect the surface finish of the final product. If the temperature is too high, it can cause the sand to break apart or result in surface defects such as roughness and pits. If the temperature is too low, it can result in incomplete casting or misalignment.

It is important to control the pouring temperature of the casting material to ensure a smooth and uniform surface finish. Using a temperature control system can help to maintain a consistent pouring temperature throughout the casting process.

Use High-Quality Release Agents

Release agents are used to prevent the casting material from sticking to the mold and to help facilitate the release of the finished casting. Using a high-quality release agent can help to improve the surface finish of the casting by reducing surface defects such as roughness and pits.

It is important to choose a release agent that is compatible with the casting material and will not cause any chemical reactions that could result in surface defects. Additionally, the release agent should be applied evenly and in the correct amount to ensure a smooth and uniform surface finish.

Properly Clean and Finish the Casting

After the casting process is complete, it is important to properly clean and finish the casting to achieve a high-quality surface finish. This includes removing any excess sand or debris from the casting, as well as smoothing out any rough or uneven areas.

Using a variety of finishing techniques such as sandblasting, polishing, or grinding can help to achieve a smooth and uniform surface finish. It is important to choose the appropriate finishing technique based on the specific casting material and desired surface finish.

Benefits of Improving Sand Casting Surface Finish

- Improved aesthetics and appearance of the finished product

- Increased durability and lifespan of the product

- Reduced risk of surface defects and imperfections

- Improved dimensional accuracy and precision

- Higher quality and more consistent casting results

Sand Casting Surface Finish vs Other Casting Methods

| Method | Advantages | Disadvantages | Surface Finish |

|---|---|---|---|

| Die Casting | High production rates, close tolerances, good surface finish | High tooling costs, limited material selection | Smooth and uniform |

| Investment Casting | High precision, complex shapes, good surface finish | Higher costs, longer lead times | Smooth and uniform |

| Lost Foam Casting | Good surface finish, low tooling costs, complex shapes | Higher energy costs, limited material selection | Smooth and uniform |

| Sand Casting | Low tooling costs, versatile, wide material selection | Limited dimensional accuracy, surface finish, and tolerances | Can vary depending on technique and materials used |

In conclusion, improving sand casting surface finish is crucial to achieving high-quality and consistent casting results. By using high-quality sand, controlling the moisture content, using the right molding techniques, controlling the pouring temperature, using high-quality release agents, and properly cleaning and finishing the casting, you can achieve a smooth and uniform surface finish. This will result in improved aesthetics, durability, and dimensional accuracy of the finished product. Understanding the advantages and disadvantages of sand casting compared to other casting methods can also help you make the best choice for your specific needs.

Frequently Asked Questions

In sand casting, achieving a smooth and high-quality surface finish is essential for the final product’s appearance and functionality. Here are some common questions and answers about how to improve sand casting surface finish.

What factors affect the surface finish of sand castings?

Several factors can affect the surface finish of sand castings, such as the type and quality of the molding sand, the casting temperature, and the metal’s composition. Other factors that can impact the surface finish include the design of the pattern and the gating system, the type of mold release agent used, and the casting’s cooling rate.

To improve the surface finish, it’s important to consider all these factors and optimize them accordingly. For example, using a high-quality molding sand and controlling the casting temperature can help reduce surface defects like roughness, pits, and sand inclusions. A well-designed gating system can also help ensure a more uniform flow of molten metal and reduce turbulence, which can lead to surface defects.

What are some common surface defects in sand castings?

Some common surface defects in sand castings include roughness, porosity, sand inclusions, and surface cracks. Roughness can be caused by inadequate surface preparation, poor mold design, or incorrect sand composition. Porosity can occur when gases are trapped in the molten metal during solidification. Sand inclusions can happen when sand particles become embedded in the casting surface. Surface cracks can occur due to thermal stresses or mechanical impacts.

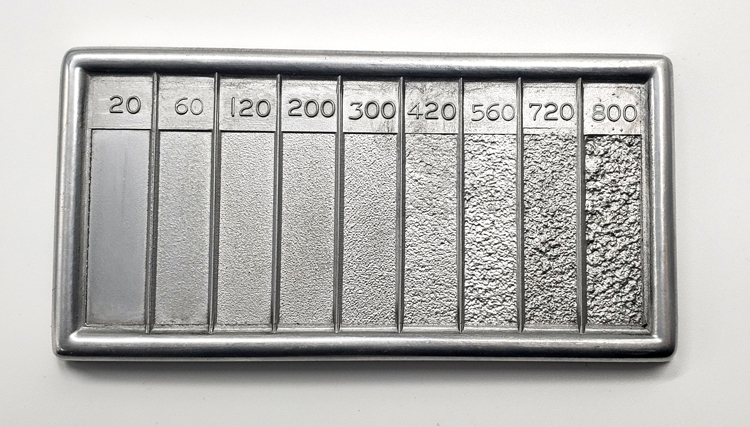

To improve the surface finish and reduce these defects, it’s essential to identify the root cause and address it accordingly. For example, roughness can be reduced by using a finer sand grain size and improving the surface preparation process. Porosity can be minimized by optimizing the casting temperature, reducing turbulence during pouring, and using a suitable mold coating. Sand inclusions can be prevented by using a higher-quality molding sand and improving the mold cleaning process. Surface cracks can be avoided by controlling the cooling rate and using suitable risers and gating systems.

How can mold coatings improve the surface finish of sand castings?

Mold coatings can help improve the surface finish of sand castings by reducing the adhesion of molten metal to the mold surface, preventing metal penetration, and enhancing the mold’s resistance to thermal shock. Mold coatings are typically made of refractory materials and applied to the mold surface before casting.

To maximize the benefits of mold coatings, it’s essential to choose the right type and apply it correctly. For example, water-based coatings are suitable for low-temperature casting and can provide a smooth surface finish. Solvent-based coatings are better for high-temperature casting and can help reduce surface defects like veining and scabbing. Additionally, the coating thickness and application method should be optimized to ensure uniform coverage and minimize defects.

What role does post-casting surface treatment play in improving sand casting surface finish?

Post-casting surface treatment can help improve the surface finish of sand castings by removing surface defects, improving surface roughness, and enhancing corrosion resistance. Some common post-casting treatments include shot blasting, grinding, polishing, and painting.

To achieve the desired surface finish, it’s important to choose the right post-casting treatment and optimize the process parameters. For example, shot blasting can help remove surface defects and improve surface roughness, but the blasting media’s size and velocity should be selected carefully to avoid damaging the casting surface. Grinding and polishing can help achieve a smoother surface finish, but the grinding wheel’s material and grit size should be chosen appropriately. Painting can help enhance the appearance and corrosion resistance of the casting, but the paint’s type and application method should be selected carefully.

How can quality control measures help improve sand casting surface finish?

Quality control measures can help improve the surface finish of sand castings by identifying and correcting defects early in the process, ensuring consistent process parameters, and optimizing the casting design and process. Some common quality control measures include visual inspection, non-destructive testing, process monitoring, and statistical process control.

To ensure effective quality control, it’s important to establish clear quality standards and procedures, train personnel on quality control techniques, and use appropriate tools and equipment. Additionally, quality control should be integrated into every stage of the casting process, from pattern making to post-casting treatment, to ensure consistent and high-quality results.

In conclusion, improving sand casting surface finish is not an impossible task. By following the right techniques and using the right equipment, you can achieve the desired finish that meets your needs. Remember to start by selecting the right sand, controlling the moisture content, and ensuring the right compaction. Additionally, using coatings and additives can improve the surface finish and reduce defects. Finally, regularly monitoring and adjusting the process can help you achieve consistent results and improve your casting quality.

In summary, sand casting is a critical process in the manufacturing industry, and achieving the right surface finish is crucial to ensure the quality of your products. With the right tools and techniques, you can improve the surface finish of your sand casting and reduce defects. By paying attention to the sand quality, moisture content, compaction, and using coatings and additives, you can achieve the desired surface finish. Also, regularly monitoring and adjusting the process can help you achieve consistent results and improve your casting quality.

To conclude, improving the surface finish of sand casting is not only good for aesthetics but also for the functionality of the product. By taking the necessary steps like selecting the right sand, maintaining the moisture content, and using coatings and additives, you can achieve the surface finish that meets your needs. Additionally, regularly monitoring and adjusting the process can help you optimize your casting quality and reduce defects. With these techniques, you can take your sand casting to the next level and produce high-quality products that meet the highest standards.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com