Table of Contents

Paragraph 1:

Surface finish is an essential aspect of manufacturing, affecting the functionality and appearance of a product. Measuring surface finish is crucial to ensure the quality and consistency of the manufactured parts. However, measuring surface finish can be a challenging task due to the wide range of techniques and equipment available.

Paragraph 2:

In this article, we will explore the different methods to measure surface finish and the factors to consider when selecting the appropriate technique. From contact-based methods to non-contact methods, we will provide an overview of each technique and its advantages and disadvantages to help you make an informed decision on how to measure surface finish for your next project.

- Choose the appropriate surface finish measurement instrument depending on the surface being measured.

- Clean the surface to be measured and ensure that it is dry.

- Place the instrument on the surface and take the reading.

- Repeat the process at different locations on the same surface to ensure accuracy.

- Report the average value of the readings as the surface finish measurement.

**How to Measure Surface Finish?**

Surface finish is an essential parameter in determining the quality of a manufactured component. It refers to the texture, roughness, and overall appearance of a surface. Measuring surface finish is crucial in ensuring that it meets the required standards and specifications. In this article, we will discuss the various methods of measuring surface finish.

**1. Surface Roughness**

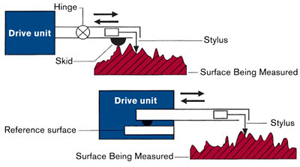

Surface roughness is the most common parameter used to measure surface finish. It refers to the fine irregularities on a surface, which are caused by the manufacturing process. These irregularities can be measured using instruments such as profilometers and surface roughness testers.

Profilometers are devices that use a stylus to measure the surface roughness. The stylus is dragged across the surface, and the device measures the height of the stylus as it moves along the surface. Surface roughness testers, on the other hand, use light to measure the surface roughness. The device shines a light on the surface, and the reflected light is analyzed to determine the surface roughness.

**2. Surface Finish Comparators**

Surface finish comparators are visual aids used to compare the surface finish of a component to a standard surface. They consist of a set of plates with different surface finishes that are used to determine the surface finish of a component. The operator compares the surface of the component to the plates until a match is found.

Surface finish comparators are simple to use and require no special training. They are ideal for use in the field or on the shop floor.

**3. Optical Microscopy**

Optical microscopy is a method of measuring surface finish that uses a microscope to magnify the surface. The microscope is equipped with a camera that captures images of the surface. The images are then analyzed to determine the surface finish.

Optical microscopy is a non-contact method of measuring surface finish, which makes it ideal for delicate components. It is also useful in measuring the surface finish of complex geometries.

**4. Scanning Electron Microscopy**

Scanning electron microscopy (SEM) is a method of measuring surface finish that uses an electron beam to scan the surface. The electrons interact with the surface, producing images that are analyzed to determine the surface finish.

SEM is useful in measuring the surface finish of very small components. It is also useful in measuring the surface finish of materials that are difficult to measure using other methods.

**5. Atomic Force Microscopy**

Atomic force microscopy (AFM) is a method of measuring surface finish that uses a cantilever to scan the surface. The cantilever is equipped with a sharp tip that interacts with the surface. The interaction between the tip and the surface produces images that are analyzed to determine the surface finish.

AFM is useful in measuring the surface finish of very small components. It is also useful in measuring the surface finish of materials that are difficult to measure using other methods.

**6. Benefits of Measuring Surface Finish**

Measuring surface finish has several benefits, including:

– Ensuring that components meet the required standards and specifications.

– Improving the performance and durability of components.

– Reducing the risk of component failure and downtime.

– Enhancing the appearance and aesthetics of components.

**7. Surface Finish vs. Surface Roughness**

Surface finish and surface roughness are often used interchangeably, but they are not the same thing. Surface finish refers to the texture, roughness, and overall appearance of a surface, while surface roughness refers to the fine irregularities on a surface.

Surface finish is a broader term that includes surface roughness. Measuring surface roughness is one method of measuring surface finish.

**8. Conclusion**

Measuring surface finish is essential in ensuring that components meet the required standards and specifications. There are several methods of measuring surface finish, including surface roughness, surface finish comparators, optical microscopy, scanning electron microscopy, and atomic force microscopy.

Each method has its advantages and disadvantages, and the choice of method depends on the component’s size, shape, and material. Measuring surface finish has several benefits, including improving the performance and durability of components and enhancing their appearance and aesthetics.

Freequently Asked Questions

Here are some frequently asked questions about how to measure surface finish:

What is surface finish?

Surface finish refers to the texture or roughness of a surface after it has been machined, polished, or otherwise worked on. Measuring surface finish can help ensure that a surface meets quality requirements and performs its intended function. Surface finish is typically measured in microinches or micrometers.

There are various methods for measuring surface finish, including profilometry, interferometry, and other optical methods. Each method has its own advantages and limitations, and the choice of method depends on factors such as the type of surface being measured, the desired level of precision, and the available equipment and resources.

Why is surface finish important?

Surface finish can affect the performance, appearance, and durability of a product or component. For example, a surface with too much roughness or unevenness can cause friction, wear, or noise, while a surface that is too smooth may not provide enough traction or adhesion. Surface finish can also affect the ability of a surface to resist corrosion, contamination, or other forms of damage.

Measuring surface finish can help ensure that a surface meets design specifications and performs its intended function, as well as identify potential problems before they become more serious. Surface finish measurements can also be used to compare different manufacturing processes, materials, or suppliers, and to optimize process parameters for better performance and efficiency.

What are some common surface finish parameters?

There are many different parameters that can be used to describe surface finish, depending on the specific application and measurement method. Some common parameters include roughness, waviness, and form. Roughness refers to the fine irregularities on a surface, while waviness refers to the larger irregularities or undulations. Form refers to the overall shape or contour of a surface, such as flatness, roundness, or cylindricity.

Each parameter is typically measured using a specific instrument or technique, and may be reported as a numerical value, a graphical representation, or a combination of both. Understanding the different parameters and how they relate to surface finish can help ensure accurate and meaningful measurements.

What are some tips for measuring surface finish?

Measuring surface finish can be a complex and challenging task, but there are some general tips that can help ensure accurate and reliable results. First, it is important to choose the most appropriate measurement method and instrument for the specific application, taking into account factors such as surface type, measurement range, and level of precision.

Second, it is important to prepare the surface properly before measuring, by cleaning, degreasing, and drying it thoroughly, and ensuring that it is free from any debris or contaminants that could affect the measurement. Finally, it is important to follow the manufacturer’s instructions for the instrument and to perform regular calibration and verification checks to ensure accurate and consistent measurements over time.

What are some common applications of surface finish measurement?

Surface finish measurement has many applications across a wide range of industries and products. Some common applications include automotive parts, aerospace components, medical devices, electronics, and consumer products such as appliances, furniture, and toys. In each case, measuring surface finish can help ensure that the product meets quality requirements and performs its intended function, as well as identify opportunities for improvement or cost savings.

Surface finish measurement can also be used for research and development purposes, such as studying the effects of different materials or manufacturing processes on surface finish, or developing new measurement techniques or standards. Overall, surface finish measurement is a critical tool for ensuring quality, reliability, and performance in many different industries and applications.

In conclusion, measuring surface finish is a crucial aspect of ensuring the quality and performance of a product. With the right tools and techniques, surface finish can be accurately measured to ensure that it meets the desired specifications. By understanding the different methods of measuring surface finish, you can select the most appropriate technique for your specific application.

Whether you are working in manufacturing, engineering or any other industry where surface finish is important, it is essential to have a clear understanding of how to measure it. By implementing the right measurement techniques and tools, you can ensure that your products meet the required standards and perform as intended.

In summary, measuring surface finish is a complex process that requires careful attention to detail and the use of specialized equipment. However, with the right knowledge and tools, it is possible to accurately measure surface finish and ensure the quality and performance of your products. So, always be diligent with your measurements and take the necessary steps to ensure that your products meet the highest standards of quality.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com