Table of Contents

- Wiring a Laser Diode Module for CNC: A Beginner’s Guide

- Freequently Asked Questions

- What is a Laser Diode Module and Why is it Used for CNC?

- What Tools and Materials Do I Need to Wire a Laser Diode Module for CNC?

- How Do I Determine the Correct Current Limiting Device for My Laser Diode Module?

- What Precautions Should I Take When Wiring a Laser Diode Module for CNC?

- How Can I Test and Troubleshoot My Laser Diode Module for CNC?

Paragraph 1: If you’re an avid CNC user, you know the importance of having a highly precise laser diode module. This tiny device can make all the difference when it comes to achieving the accuracy and precision you need for your projects. But how do you wire a laser diode module for CNC? In this guide, we’ll explore everything you need to know to make sure your laser diode module is wired correctly, so you can get back to creating your masterpieces with confidence.

Paragraph 2: Whether you’re a professional CNC user or a hobbyist, wiring a laser diode module can be a daunting task. With so many wires and connections to navigate, it’s easy to feel overwhelmed. But fear not, we’re here to help. In this guide, we’ll break down the wiring process step-by-step, so even those new to CNC can feel confident in their ability to wire a laser diode module.

How to Wire Laser Diode Module for CNC?

To wire a laser diode module for CNC, follow these steps:

- Identify the positive and negative terminals of the laser diode module.

- Connect the positive terminal to a constant current driver and the negative terminal to the driver’s negative input.

- Connect the driver to the CNC controller board.

- Adjust the current limit on the driver to regulate the laser power.

- Attach the laser diode module to the CNC machine.

- Test the laser by issuing commands through the CNC software.

Wiring a Laser Diode Module for CNC: A Beginner’s Guide

Laser diodes are a common component in many CNC machines, and they are used for cutting, engraving, and marking materials such as wood, plastic, and metal. Wiring a laser diode module can be a daunting task for those who are new to CNC machines. In this article, you will learn how to wire a laser diode module for CNC, step by step.

Understanding the Laser Diode Module

A laser diode is a semiconductor device that emits a narrow beam of light through stimulated emission. The laser diode module consists of a laser diode, a driver circuit, and a housing. The driver circuit regulates the current and voltage that is supplied to the laser diode. The housing protects the laser diode from damage and allows for easy mounting on the CNC machine.

To wire a laser diode module for CNC, you need to understand the pinout of the laser diode and the driver circuit. The pinout is the arrangement of pins on the laser diode and the driver circuit. The pinout varies depending on the manufacturer and the model of the laser diode module. Always refer to the data sheet or the manual provided by the manufacturer for the correct pinout.

Connecting the Laser Diode Module to the Driver Circuit

Before connecting the laser diode module to the driver circuit, ensure that the driver circuit is compatible with the laser diode. The driver circuit should be able to supply the correct current and voltage to the laser diode. Failure to use a compatible driver circuit can damage the laser diode or cause it to malfunction.

To connect the laser diode module to the driver circuit, follow these steps:

1. Identify the pinout of the laser diode and the driver circuit.

2. Connect the positive terminal of the laser diode to the positive terminal of the driver circuit.

3. Connect the negative terminal of the laser diode to the negative terminal of the driver circuit.

4. If the driver circuit has a potentiometer, adjust it to regulate the current supplied to the laser diode. Refer to the data sheet or the manual for the recommended current.

Mounting the Laser Diode Module on the CNC Machine

After connecting the laser diode module to the driver circuit, mount the laser diode module on the CNC machine. The mounting method varies depending on the type of CNC machine and the laser diode module. Always refer to the manual provided by the manufacturer for the correct mounting method.

To mount the laser diode module on the CNC machine, follow these steps:

1. Identify the mounting holes on the laser diode module.

2. Identify the mounting holes on the CNC machine.

3. Align the mounting holes on the laser diode module with the mounting holes on the CNC machine.

4. Secure the laser diode module to the CNC machine using screws or bolts.

Benefits of Using a Laser Diode Module in CNC

Using a laser diode module in CNC has several benefits, including:

1. High precision: Laser diodes are capable of producing a narrow beam of light that can cut or engrave materials with high precision.

2. Versatility: Laser diodes can be used to cut, engrave, or mark various materials such as wood, plastic, and metal.

3. Speed: Laser diodes can cut or engrave materials at a faster speed than other cutting tools.

4. Low maintenance: Laser diodes require low maintenance compared to other cutting tools.

Laser Diode Module vs Other Cutting Tools

Laser diode modules have several advantages over other cutting tools, including:

1. Higher precision: Laser diodes can produce a narrow beam of light that can cut or engrave materials with high precision.

2. Versatility: Laser diodes can be used to cut, engrave, or mark various materials such as wood, plastic, and metal.

3. Speed: Laser diodes can cut or engrave materials at a faster speed than other cutting tools.

4. Lower maintenance: Laser diodes require low maintenance compared to other cutting tools.

However, laser diode modules also have some disadvantages, including:

1. Cost: Laser diode modules can be more expensive than other cutting tools.

2. Safety: Laser diodes can be hazardous if not used properly. Always wear appropriate safety gear and follow the safety instructions provided by the manufacturer.

Conclusion

Wiring a laser diode module for CNC is an essential skill for those who want to use laser cutting or engraving on their CNC machines. By following the steps outlined in this article, you can wire a laser diode module safely and efficiently. Remember to always refer to the data sheet or the manual provided by the manufacturer for the correct pinout, current, and mounting method.

Freequently Asked Questions

In this section, you’ll find answers to some of the most common questions about wiring a laser diode module for CNC. Read on to find out more.

What is a Laser Diode Module and Why is it Used for CNC?

A laser diode module is a small, self-contained device that contains a semiconductor laser diode, a lens to focus the laser beam, and a driver circuit to regulate the power to the diode. It is used in CNC machines to create precise cuts and engravings on a variety of materials, including wood, plastic, and metal. The laser beam can be controlled with high accuracy and speed, making it a popular tool for manufacturing and prototyping.

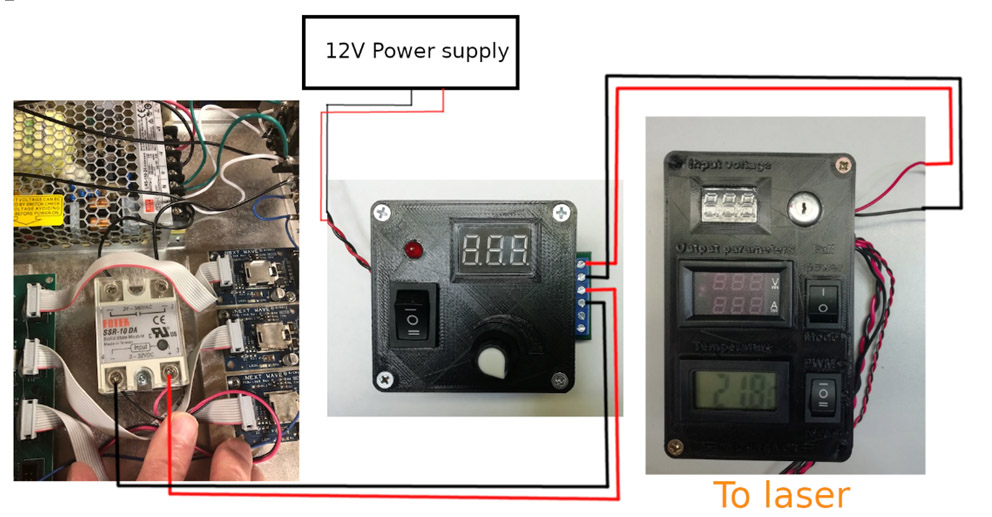

When wiring a laser diode module for CNC, it’s important to follow the manufacturer’s instructions carefully to ensure safe and effective operation. The module will typically require a DC power supply and an appropriate current-limiting device to protect the diode from damage.

What Tools and Materials Do I Need to Wire a Laser Diode Module for CNC?

To wire a laser diode module for CNC, you will need a few basic tools and materials. These may include a soldering iron, wire strippers, electrical tape or heat shrink tubing, a DC power supply, a current-limiting device (such as a resistor or adjustable voltage regulator), and a suitable connector or terminal block to connect the module to your CNC control board.

It’s also important to have a clear understanding of the wiring diagram provided by the module manufacturer, as well as any safety precautions or warnings that may be included in the documentation.

How Do I Determine the Correct Current Limiting Device for My Laser Diode Module?

The correct current-limiting device for your laser diode module will depend on the specific characteristics of the module and the power supply you are using. It’s important to review the module’s documentation carefully to determine the recommended operating parameters, including the maximum current and voltage ratings.

Once you have this information, you can choose an appropriate current-limiting device based on its resistance or voltage drop characteristics. A resistor or adjustable voltage regulator may be used, depending on the requirements of your system. Be sure to select a device that can handle the maximum current and voltage output of your power supply, and follow the manufacturer’s recommendations for wiring and installation.

What Precautions Should I Take When Wiring a Laser Diode Module for CNC?

Wiring a laser diode module for CNC requires careful attention to safety and proper installation practices. Some important precautions to keep in mind include:

- Always wear eye protection when working with lasers, and avoid looking directly at the beam.

- Make sure the power supply is disconnected and the module is discharge before handling or connecting any wires.

- Use appropriate electrical insulation and strain relief to prevent accidental shorts or damage to the module.

- Follow the manufacturer’s instructions carefully, and double-check all connections and wiring before powering up the system.

By taking these precautions and following best practices for wiring and installation, you can help ensure safe and effective operation of your laser diode module for CNC.

How Can I Test and Troubleshoot My Laser Diode Module for CNC?

If you experience problems with your laser diode module for CNC, it’s important to take a systematic approach to testing and troubleshooting the system. This may involve checking the wiring and connections, verifying the power supply and current-limiting device settings, and testing the module with a digital multimeter or oscilloscope.

If you are unable to resolve the issue on your own, it may be helpful to consult the module’s documentation or contact the manufacturer for technical support. In some cases, you may need to replace the module or seek professional assistance to resolve the problem.

In conclusion, wiring a laser diode module for CNC can seem daunting at first, but with the right tools and knowledge, it can be a straightforward process. The key is to take your time and follow the instructions carefully. Once you have successfully wired your laser diode module, you can enjoy the benefits of improved precision and accuracy in your CNC projects.

Remember to always prioritize safety when working with laser diodes. Wear protective eyewear and follow all recommended safety precautions. It is also essential to choose a high-quality laser diode module to ensure optimal performance and longevity.

Finally, don’t be afraid to seek out additional resources and support if you need it. There are many online communities and forums dedicated to CNC and laser technology, where you can ask questions and connect with other enthusiasts. With determination and a willingness to learn, you can master the art of wiring laser diode modules for CNC and take your projects to the next level.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com