If you’re looking to add a laser module to your 3018 CNC machine, you’ve come to the right place. Wiring a laser module can be a daunting task, but with the right guidance, it can be a breeze. In this article, we’ll take you through the steps needed to wire a laser module for your 3018 CNC machine.

First, we’ll go over the materials you’ll need, then move onto the wiring process itself. Whether you’re a beginner or a seasoned pro, this guide will provide you with all the information you need to successfully wire a laser module for your 3018 CNC machine. So, let’s get started!

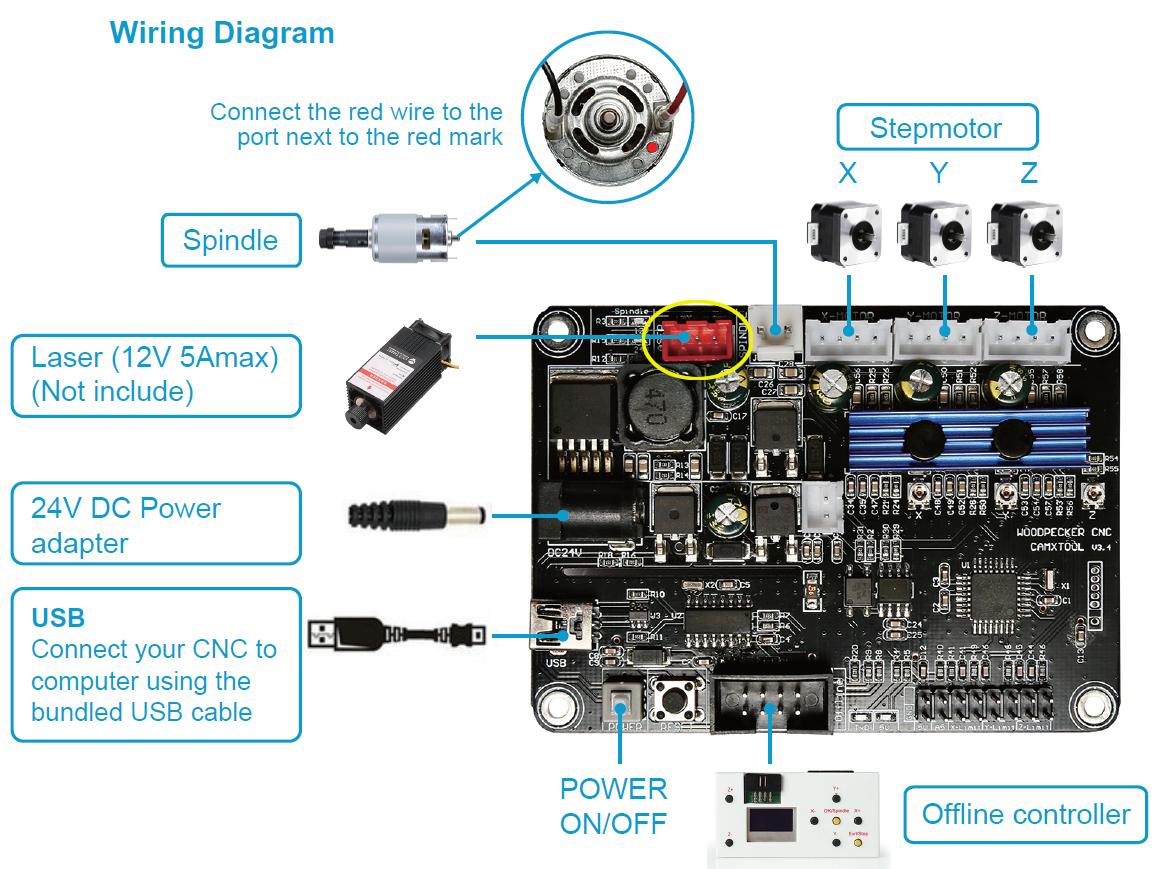

- Firstly, connect the laser module to the power supply source.

- Then, connect the TTL signal wire to the CNC controller’s spindle speed control signal output.

- Next, connect the laser module’s ground wire to the CNC controller’s ground terminal.

- After that, connect the laser module’s positive wire to the CNC controller’s 12V or 24V terminal.

- Finally, test the laser by running a G-code program that includes laser control commands.

Wiring a Laser Module for Your 3018 CNC Machine:

If you’re looking to add a laser module to your 3018 CNC machine, you’re in the right place. Wiring a laser module can seem daunting, but with the right tools and some knowledge, it’s a straightforward process. In this article, we’ll go through the steps to wire a laser module for your 3018 CNC machine.

Step 1: Gather the Required Tools

Before you start wiring, make sure you have all the necessary tools. You’ll need a soldering iron, solder wire, wire strippers, and heat-shrink tubing. It’s also a good idea to have a multimeter to check your connections.

The Required Tools:

- Soldering iron

- Solder wire

- Wire strippers

- Heat-shrink tubing

- Multimeter

Step 2: Identify the Correct Pins

The laser module will typically have three pins: positive, negative, and control. The positive and negative pins are for power, and the control pin is for the CNC machine to turn the laser on and off. You’ll need to identify which pins are which, as they may not be labeled.

Identifying the Correct Pins:

| Pin | Function |

|---|---|

| Positive | Power |

| Negative | Ground |

| Control | Laser On/Off |

Step 3: Connect the Laser Module to the CNC Machine

Once you’ve identified the correct pins, the next step is to connect the laser module to the CNC machine. You’ll need to find the appropriate pins on the CNC machine’s control board and connect them to the laser module.

Connecting the Laser Module to the CNC Machine:

- Find the pins on the control board for the laser module.

- Connect the positive pin from the laser module to the positive pin on the control board.

- Connect the negative pin from the laser module to the negative pin on the control board.

- Connect the control pin from the laser module to the control pin on the control board.

Step 4: Test the Connection

Before you start using the laser module, it’s essential to test the connection. Use a multimeter to check that the correct voltage is flowing through the circuit. You can also try turning the laser on and off using the CNC machine’s software.

Testing the Connection:

- Use a multimeter to check the voltage at each pin.

- Test the laser module by turning it on and off using the CNC machine’s software.

Step 5: Install the Laser Module

Now that you’ve wired and tested the laser module, it’s time to install it on your CNC machine. Follow the manufacturer’s instructions for installation and alignment.

Installing the Laser Module:

- Follow the manufacturer’s instructions for installation.

- Align the laser module with the CNC machine’s cutting head.

Benefits of Adding a Laser Module to Your CNC Machine

Adding a laser module to your CNC machine can open up a whole new range of possibilities. You can use it for engraving, cutting, and even 3D printing. Laser modules are also more precise than traditional cutting tools and can create intricate designs.

Benefits of Adding a Laser Module:

- Enables engraving and cutting.

- Allows for more precise designs.

- Opens up new possibilities for 3D printing.

Laser Module vs. Traditional Cutting Tools

Compared to traditional cutting tools, laser modules have several advantages. They are more precise, can cut through thicker materials, and can create intricate designs. However, they are also more expensive and require more maintenance.

Laser Module vs. Traditional Cutting Tools:

- More precise.

- Can cut through thicker materials.

- Create intricate designs.

- More expensive.

- Require more maintenance.

In conclusion, wiring a laser module for your 3018 CNC machine is a straightforward process. By following these steps and using the right tools, you can quickly add a laser module to your CNC machine and start exploring new design possibilities.

Freequently Asked Questions

In this section, you will find answers to some of the most commonly asked questions about wiring a laser module for a 3018 CNC machine. Whether you are a beginner or an experienced user, these questions and answers will help you get started with your laser module wiring.

What is a Laser Module for 3018 CNC?

A laser module is a powerful tool that can be attached to a 3018 CNC machine to perform various cutting and engraving tasks. It emits a concentrated beam of light that is capable of cutting through or engraving on a variety of materials such as wood, acrylic, leather, and plastic. Wiring a laser module to a 3018 CNC machine is a simple process that involves connecting the laser module to the power supply and the control board of the machine.

Before wiring the laser module, it is important to ensure that you have the right tools and equipment for the job. You will need a soldering iron, solder, wire strippers, and heat shrink tubing. You should also have a good understanding of the wiring diagram of your 3018 CNC machine and the laser module.

Why Do You Need to Wire a Laser Module for 3018 CNC?

Wiring a laser module to a 3018 CNC machine is necessary if you want to use the laser for cutting or engraving tasks. Without the proper wiring, the laser module will not be able to function, and you will not be able to perform any laser-related tasks. By wiring the laser module, you can control the laser power and intensity, and you can also adjust the focus of the laser beam to achieve the desired results.

It is important to note that wiring a laser module can be dangerous if not done correctly. The laser beam is powerful, and if it is not properly controlled, it can cause serious injury or damage. Therefore, it is crucial to follow the wiring instructions carefully and to take all necessary safety precautions when working with the laser module.

What are the Steps for Wiring a Laser Module for 3018 CNC?

The first step in wiring a laser module for a 3018 CNC machine is to gather all the necessary tools and equipment. Once you have everything you need, you can begin by connecting the laser module to the power supply of the machine. Next, you will need to connect the laser control wire to the control board of the machine.

After making these connections, you should test the laser module to ensure that it is functioning properly. Finally, you will need to adjust the laser focus to achieve the desired results. This can be done by moving the laser module closer or further away from the material you are working on, or by adjusting the lens of the laser module.

What Precautions Should You Take When Wiring a Laser Module for 3018 CNC?

When wiring a laser module for a 3018 CNC machine, it is important to take all necessary safety precautions to prevent injury or damage. You should wear safety glasses to protect your eyes from the laser beam, and you should avoid looking directly at the laser beam.

You should also ensure that the laser module is properly grounded to prevent any electrical shocks. Additionally, you should follow the wiring instructions carefully and double-check all connections before powering on the machine. If you are unsure about any aspect of the wiring process, you should seek the advice of a professional or an experienced user.

What Are Some Tips for Wiring a Laser Module for 3018 CNC?

Here are some tips to help you wire a laser module for a 3018 CNC machine:

- Read the wiring instructions carefully and follow them step-by-step.

- Double-check all connections before powering on the machine.

- Use the right tools and equipment for the job, including a soldering iron, solder, wire strippers, and heat shrink tubing.

- Ensure that the laser module is properly grounded to prevent electrical shocks.

- Take all necessary safety precautions, including wearing safety glasses and avoiding direct exposure to the laser beam.

By following these tips, you can ensure that your laser module is properly wired and functioning safely and effectively.

In conclusion, wiring a laser module for a 3018 CNC can seem like a daunting task, but with the right tools and knowledge, it can be done easily and efficiently. It is important to ensure that safety measures are taken seriously and that the correct wiring procedures are followed to avoid any damage or harm.

Remember to always use protective gear when working with lasers, and to double-check your wiring before turning on the laser. By taking the time to properly wire your laser module, you can greatly enhance the functionality of your CNC machine and take your projects to the next level.

In summary, wiring a laser module for a 3018 CNC may require some effort and patience, but the results are well worth it. With a little bit of practice and attention to detail, you can enjoy the precise and accurate laser cutting and engraving capabilities that this technology has to offer.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com