Table of Contents

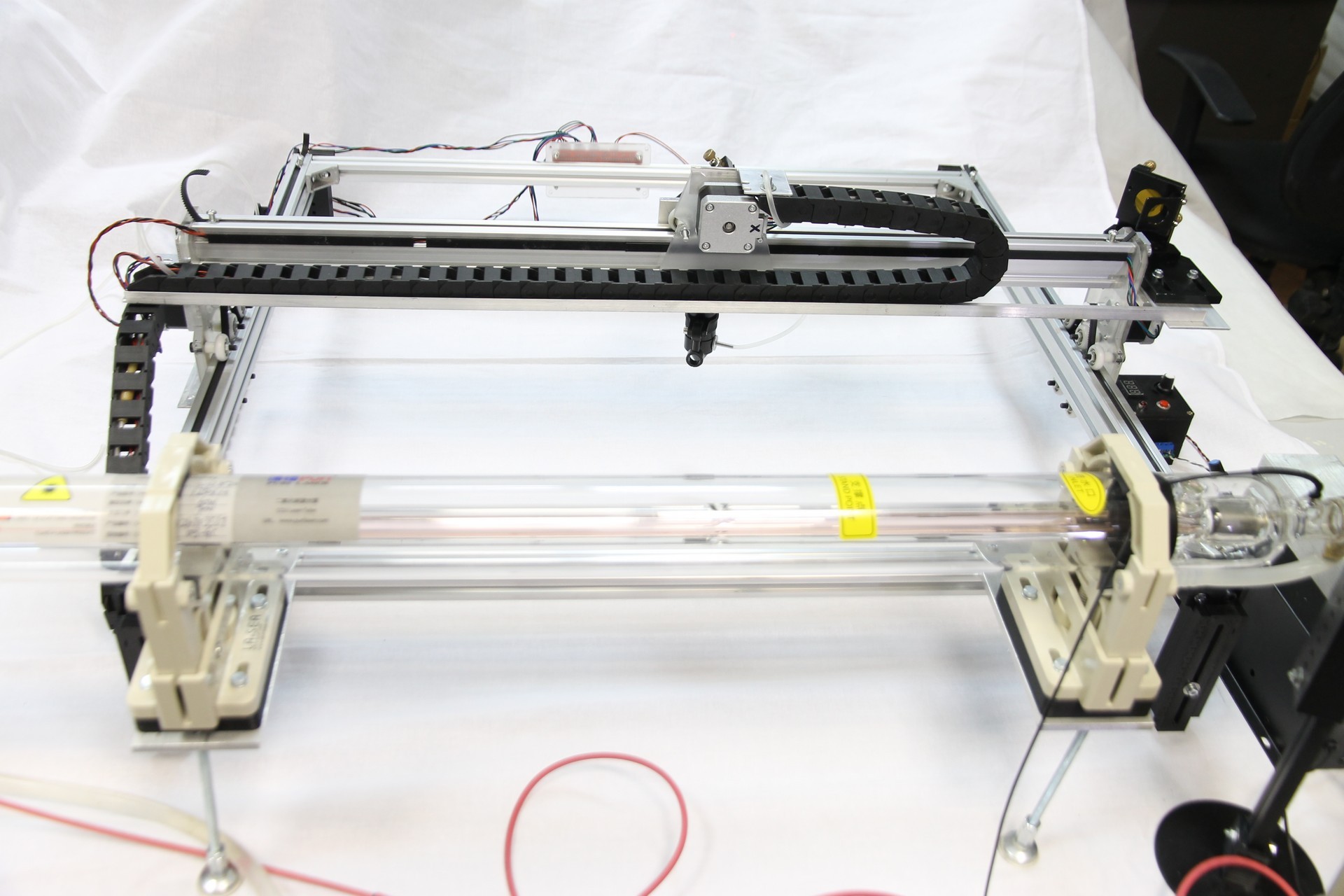

CNC laser machines have revolutionized the way we cut and engrave materials. These machines use a laser beam to create precise cuts and designs on various materials, from wood to metal. One type of CNC laser machine that has gained popularity in recent years is the CO2 CNC laser, which uses a carbon dioxide laser to cut through materials.

So, what goes into a CO2 CNC laser? These machines are made up of several components, including the laser tube, power supply, mirrors, lenses, and software. Each of these parts plays a crucial role in the machine’s ability to cut and engrave materials with precision and accuracy. In this article, we will take a closer look at each component and how they work together to create a CO2 CNC laser machine.

What Goes Into a Co2 CNC Laser?

If you’re looking to invest in a CNC laser, you’ll likely come across the term “Co2 CNC laser.” But what exactly goes into this type of laser cutter? In this article, we’ll break down the components of a Co2 CNC laser and what you can expect from this technology.

1. Laser Tube

The laser tube is the heart of a Co2 CNC laser. It’s responsible for producing the laser beam that cuts or engraves materials. The tube is filled with a mixture of gases, including carbon dioxide, nitrogen, helium, and hydrogen. When an electrical current is applied to the gases, they ionize and release energy in the form of a laser beam.

Most Co2 CNC lasers use glass tubes to house the gas mixture, while newer models may use metal or ceramic tubes. Glass tubes are generally cheaper but have a shorter lifespan compared to metal or ceramic tubes.

Benefits of a Co2 CNC laser with a glass tube include lower cost and easier replacement. Metal or ceramic tubes, on the other hand, have the benefit of a longer lifespan and higher power output.

2. Mirrors and Lenses

Once the laser beam is produced, it needs to be directed onto the material being cut or engraved. This is where mirrors and lenses come into play. The laser beam is reflected off a series of mirrors before passing through a focusing lens that concentrates the beam onto the material.

The quality of the mirrors and lenses is crucial to the performance of the CNC laser. High-quality components ensure a consistent and accurate laser beam, while lower-quality components can result in a weaker or less precise beam.

3. CNC Controller

The CNC controller is the brains of the Co2 CNC laser. It’s responsible for controlling the movement of the laser head as it cuts or engraves the material. The controller reads the G-code file, which contains the instructions for the laser, and sends signals to the motors that move the laser head.

Modern CNC controllers are typically computer-based and use software to control the laser. This allows for greater precision and flexibility in the cutting and engraving process.

4. Motors and Drive Systems

The motors and drive systems are responsible for moving the laser head along the X and Y axes. Stepper motors are commonly used in Co2 CNC lasers due to their accuracy and low cost. The motors are controlled by the CNC controller, which sends signals to the motor driver to move the laser head.

Drive systems can be either belt-driven or screw-driven. Belt-driven systems are generally faster but less accurate than screw-driven systems.

5. Cooling System

The laser tube and other components of the Co2 CNC laser generate a lot of heat during operation. A cooling system is required to prevent the components from overheating and causing damage.

Most Co2 CNC lasers use a water-based cooling system. Water is circulated through the laser tube and other components to absorb heat and dissipate it through a radiator. A pump is used to circulate the water through the system.

6. Exhaust System

The cutting and engraving process generates smoke and fumes that can be harmful to the operator and the environment. An exhaust system is used to remove these byproducts from the work area.

The exhaust system typically consists of a fan, ducting, and a filter. The fan draws the smoke and fumes through the ducting and into the filter, which removes the harmful particles before releasing the air back into the environment.

7. Power Supply

The power supply is responsible for providing the electrical current needed to ionize the gas mixture in the laser tube. The power supply converts the AC voltage from the wall outlet into a high-voltage DC current that is used to power the laser.

The power supply is an essential component of the Co2 CNC laser, as it directly affects the power output and performance of the laser.

8. Worktable

The worktable is the surface on which the material being cut or engraved is placed. Most Co2 CNC lasers use a flat bed worktable, which allows for a wide range of materials to be cut or engraved.

Some Co2 CNC lasers may have a rotary attachment that allows for cylindrical objects to be engraved. The worktable may also have a honeycomb design to provide support for materials that may not lay flat on the worktable.

9. User Interface

The user interface is the way in which the operator interacts with the Co2 CNC laser. This may include a control panel with buttons and a screen, or a software-based interface that is accessed through a computer.

The user interface allows the operator to control the laser, adjust settings, and monitor the cutting or engraving process. A user-friendly interface is essential for ensuring efficient and accurate operation of the Co2 CNC laser.

10. Maintenance and Support

Finally, maintenance and support are crucial factors to consider when investing in a Co2 CNC laser. Regular maintenance is required to ensure the laser is operating at peak performance and to prevent breakdowns or damage to components.

Additionally, reliable technical support is essential in the event of any issues or questions that may arise during operation. When purchasing a Co2 CNC laser, be sure to consider the availability and quality of maintenance and support services.

In conclusion, a Co2 CNC laser is a complex piece of machinery that requires a range of components working together to produce accurate and precise cuts and engravings. By understanding the components that go into a Co2 CNC laser, you can make an informed decision when investing in this technology.

Freequently Asked Questions

What is a Co2 CNC Laser?

A Co2 CNC Laser is a laser machine that uses a carbon dioxide laser to cut and engrave materials. The laser beam is directed onto the material using a computer-controlled system, which allows for precise and accurate cuts.

The laser is powered by a high-voltage electrical discharge that excites the CO2 gas mixture in the laser tube, causing it to emit a concentrated beam of light in the infrared spectrum. This beam is then focused onto the material being cut or engraved, vaporizing it and leaving a clean, precise cut or engraving.

What goes into a Co2 CNC Laser?

A Co2 CNC Laser consists of several key components, including a laser tube, power supply, mirrors, lens, and a computer-controlled system. The laser tube is the heart of the machine, producing the laser beam that is used to cut and engrave materials.

The power supply provides the high-voltage electrical discharge that excites the CO2 gas mixture in the laser tube, while the mirrors and lens focus the laser beam onto the material being cut or engraved. The computer-controlled system controls the movement of the laser beam and ensures that the cuts and engravings are precise and accurate.

What materials can be cut with a Co2 CNC Laser?

A Co2 CNC Laser can cut a wide range of materials, including wood, acrylic, plastic, leather, fabric, and paper. The laser beam can also be used to engrave materials, such as glass, marble, and metal.

The ability to cut and engrave a variety of materials makes Co2 CNC Lasers ideal for a range of applications, including signage, jewelry making, woodworking, and industrial manufacturing.

How does a Co2 CNC Laser work?

A Co2 CNC Laser works by directing a laser beam onto the material being cut or engraved. The laser beam is produced by exciting a CO2 gas mixture in a laser tube using a high-voltage electrical discharge.

The beam is then focused onto the material using mirrors and a lens, vaporizing it and leaving a clean, precise cut or engraving. The computer-controlled system ensures that the laser beam is directed accurately to achieve the desired cut or engraving.

What are the advantages of using a Co2 CNC Laser?

Co2 CNC Lasers offer several advantages over traditional cutting and engraving methods. They provide precise and accurate cuts and engravings, allowing for complex designs and detailed work.

They are also faster and more efficient than traditional methods, allowing for higher production rates and reduced labor costs. Additionally, Co2 CNC Lasers are versatile and can be used to cut and engrave a wide range of materials, making them ideal for a variety of applications.

In conclusion, a CO2 CNC laser is a complex piece of machinery that requires careful consideration of multiple factors. Understanding the gas flow, mirrors, lenses, and power source is crucial to creating a successful laser cutter. It is important to remember that every component of the machine plays a vital role in the overall performance of the laser.

Aside from these components, the operator’s skills and knowledge of the machine also play a crucial part in the success of the laser cutting process. Without proper training and experience, even the most advanced machine may not perform optimally.

In today’s world, where precision and speed are essential, a CO2 CNC laser has become a valuable tool in many industries. From automotive manufacturing to electronics, this technology is revolutionizing the way we approach manufacturing. With continuous advancements in technology, it is exciting to see what the future holds for CO2 CNC lasers and their capabilities.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com