Table of Contents

Have you ever wondered how plastic products are mass-produced? Look no further than injection molding. This manufacturing process is widely used in various industries due to its efficiency, versatility, and cost-effectiveness.

Injection molding involves melting plastic pellets and injecting the molten material into a mold, creating a 3D shape. The possibilities are endless with this process, from creating simple components to intricate designs. In this article, we’ll explore the advantages of injection molding and why it’s the go-to method for producing high-quality plastic products.

Why Use Injection Molding?

Injection molding is a popular manufacturing process used to produce a wide range of plastic products. It involves injecting molten plastic material into a molding cavity, where it solidifies and takes the shape of the cavity. Injection molding is versatile, cost-effective, and efficient, making it a preferred choice for many manufacturers. In this article, we’ll explore the benefits of injection molding and why it’s worth considering for your next project.

High Efficiency

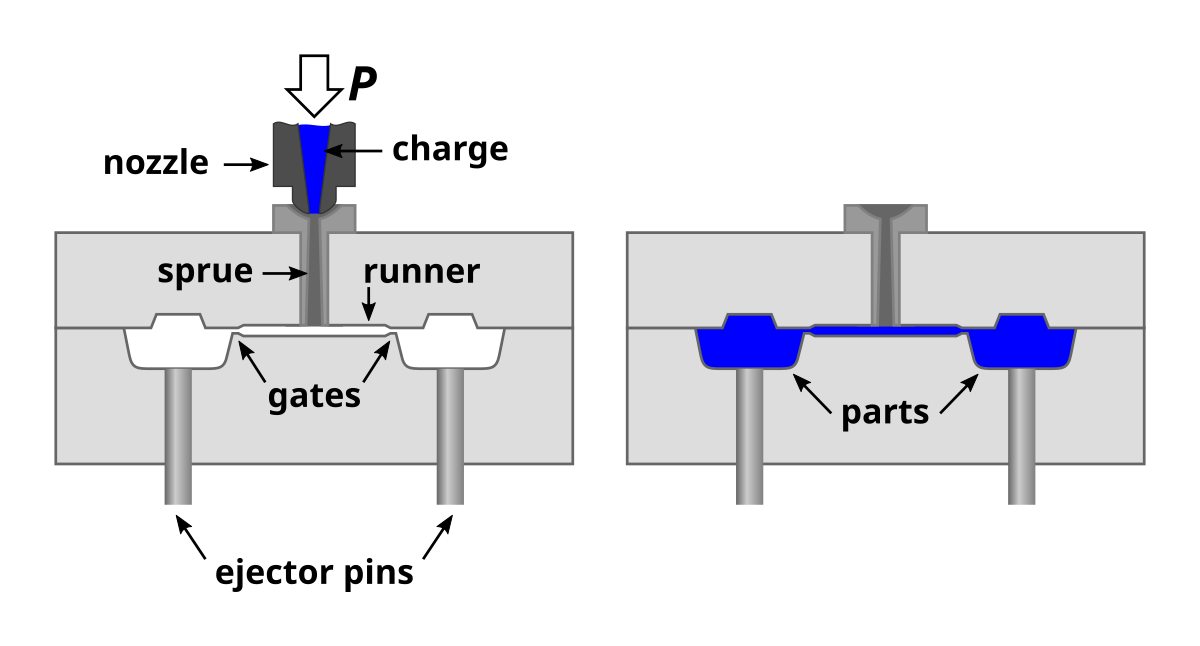

Injection molding is a highly efficient process that allows for the mass production of identical parts. The process involves using a specially designed machine to inject molten plastic into a mold. The mold is then cooled and the plastic solidifies, creating a finished product. This process can be repeated thousands of times, making it ideal for mass production.

Injection molding also allows for high production rates, reducing the time and cost associated with producing each part. This makes it a cost-effective option for manufacturers looking to produce large quantities of parts quickly and efficiently.

Design Flexibility

Injection molding offers a high degree of design flexibility, allowing manufacturers to create complex parts with intricate geometries. The process allows for the creation of parts with varying thicknesses, textures, and colors, and can be used to produce parts with multiple components.

Injection molding also allows for the use of a wide range of materials, including thermoplastics, thermosets, and elastomers. This versatility makes it a popular choice for a wide range of applications, from medical devices to automotive parts.

Accuracy and Consistency

Injection molding offers a high degree of accuracy and consistency, ensuring that each part is identical to the last. The process allows for tight tolerances, ensuring that parts fit together perfectly and function as intended.

Injection molding machines are equipped with sophisticated control systems that allow for precise control over the injection process. This ensures that the amount of material injected into the mold is consistent, resulting in parts with uniform wall thicknesses and dimensions.

Reduced Waste

Injection molding is a highly efficient process that generates minimal waste. The process involves using only the amount of material needed to produce the part, reducing material waste and minimizing the environmental impact of the manufacturing process.

Injection molding also allows for the use of recycled materials, further reducing the environmental impact of the process. This makes it a popular choice for manufacturers looking to reduce their carbon footprint and adopt more sustainable manufacturing practices.

Cost-Effective

Injection molding is a cost-effective process that offers a high degree of efficiency, accuracy, and consistency. The process allows for the mass production of identical parts at a relatively low cost per part. This makes it a popular choice for manufacturers looking to produce large quantities of parts quickly and efficiently.

Injection molding also offers a high degree of automation, reducing the need for manual labor and further reducing the cost of production. This makes it a cost-effective option for manufacturers of all sizes and industries.

Customization

Injection molding allows for a high degree of customization, making it ideal for producing parts with unique designs and specifications. The process allows for the creation of parts with varying thicknesses, textures, and colors, and can be used to produce parts with multiple components.

Injection molding also allows for the use of inserts, allowing manufacturers to add metal or other materials to the part during the molding process. This allows for the creation of parts with unique properties or functions.

Fast Production

Injection molding offers fast production rates, allowing manufacturers to produce large quantities of parts quickly and efficiently. The process can be automated, further reducing the time and cost associated with production.

Injection molding also allows for the use of multiple molds, allowing manufacturers to produce different parts simultaneously. This makes it a popular choice for manufacturers looking to increase their production capacity and efficiency.

Quality Control

Injection molding offers a high degree of quality control, ensuring that each part is identical to the last. The process allows for tight tolerances, ensuring that parts fit together perfectly and function as intended.

Injection molding machines are equipped with sophisticated control systems that allow for precise control over the injection process. This ensures that each part is produced to the same high standard, minimizing the risk of defects or flaws.

Low Maintenance

Injection molding machines are designed for low maintenance, reducing the need for frequent repairs or replacement parts. The machines are built to last, with durable components that can withstand the rigors of high-volume production.

Injection molding machines also offer a high degree of automation, reducing the need for manual labor and further reducing the risk of maintenance issues. This makes it a cost-effective option for manufacturers looking to minimize downtime and maximize production efficiency.

Versatility

Injection molding is a versatile process that can be used to produce a wide range of parts for a wide range of industries. The process allows for the use of a wide range of materials, including thermoplastics, thermosets, and elastomers.

Injection molding can be used to produce parts for industries such as automotive, medical, electronics, and consumer products. This versatility makes it a popular choice for manufacturers looking to produce high-quality parts for a variety of applications.

In conclusion, injection molding offers a wide range of benefits, including high efficiency, design flexibility, accuracy and consistency, reduced waste, cost-effectiveness, customization, fast production, quality control, low maintenance, and versatility. These benefits make it a popular choice for manufacturers of all sizes and industries looking to produce high-quality plastic parts quickly, efficiently, and cost-effectively.

Frequently Asked Questions

Injection molding is a popular manufacturing method used in producing plastic parts in large quantities. Here are some frequently asked questions about why you should use injection molding.

What is injection molding?

Injection molding is a manufacturing process used for mass-producing plastic parts. It involves injecting melted plastic material into a mold cavity, where it cools and hardens to the desired shape. The process is highly automated and can produce complex shapes and designs with consistent quality and precision.

Injection molding is a cost-effective method for producing large quantities of plastic parts. The tooling costs for creating the molds can be high, but the per-unit cost decreases as the volume increases. This makes injection molding ideal for large-scale production runs.

Why use injection molding?

Injection molding offers several advantages over other manufacturing methods. It allows for the creation of complex shapes and designs with consistent quality and precision. The process is highly automated, which reduces labor costs and increases efficiency. Injection molding also produces less waste compared to other methods, as any excess plastic can be re-melted and reused.

Injection molding is also a versatile process, as it can produce parts of various sizes, shapes, and materials. It can produce parts with high strength and durability, making it suitable for use in various industries such as automotive, medical, and consumer electronics.

What materials can be used in injection molding?

Injection molding can use a wide range of thermoplastics, such as ABS, polycarbonate, nylon, and PVC. It can also use thermosetting plastics, such as phenolic and epoxy resins. The choice of material depends on the specific requirements of the part being produced, such as its strength, durability, and temperature resistance.

Injection molding can also use additives, such as colorants, UV stabilizers, and flame retardants, to enhance the properties of the plastic material. This allows for greater flexibility in creating parts that meet specific performance requirements.

What is the process of injection molding?

The injection molding process consists of several steps. First, the plastic material is melted and injected into a mold cavity. The mold is then cooled to allow the plastic to solidify and take on the desired shape. The mold is then opened, and the finished part is ejected.

The process is highly automated and can be controlled using computer software to ensure consistent quality and precision. The molds can also be customized to create parts with specific features or designs.

What are the advantages of injection molding over other methods?

Injection molding offers several advantages over other manufacturing methods. It allows for the creation of complex shapes and designs with consistent quality and precision. The process is highly automated, which reduces labor costs and increases efficiency. Injection molding also produces less waste compared to other methods, as any excess plastic can be re-melted and reused.

Injection molding is also a versatile process, as it can produce parts of various sizes, shapes, and materials. It can produce parts with high strength and durability, making it suitable for use in various industries such as automotive, medical, and consumer electronics.

In today’s fast-paced world, the need for quality products in a timely and cost-effective manner has never been greater. That’s why injection molding has become such a popular manufacturing method. But why use injection molding, you may ask? Here are three compelling reasons.

Firstly, injection molding is highly versatile. This method allows for the production of intricate and complex shapes, which would be difficult or impossible to achieve with other manufacturing processes. Additionally, injection molding can accommodate a wide range of materials, including plastics, metals, and even glass.

Secondly, injection molding is incredibly efficient. Once the mold is created, the production process can be automated, which means high-volume production runs can be achieved with minimal labor costs. Additionally, the precision of injection molding means there is little to no waste, which translates to significant cost savings.

Finally, injection molding is an environmentally friendly manufacturing method. The automation and precision of injection molding mean that there is much less material waste and energy usage compared to other methods. Additionally, many of the materials used in injection molding are recyclable, which further reduces environmental impact.

In conclusion, there are many compelling reasons to use injection molding as a manufacturing method. Its versatility, efficiency, and environmental friendliness make it an attractive choice for any company looking to produce quality products in a timely and cost-effective manner.

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com