Table of Contents

As a CNC laser user, you know that focus is critical to producing high-quality cuts and engravings. But how can you be sure that your laser is properly focused?

In this article, we’ll explore some of the most common methods for checking your CNC laser’s focus, as well as some tips for maintaining optimal focus over time. Whether you’re a seasoned pro or just getting started with CNC laser cutting and engraving, understanding focus is key to achieving the best possible results.

To check if your CNC laser is focused, you can perform a simple focus test. Take a piece of material, preferably the same material you will be working on, and make a small mark on it with the laser. If the mark is crisp and clean, then your laser is focused. If the mark is blurry or has angled edges, then you need to adjust the focus. Repeat the test until you achieve a clean and crisp mark.

How Do I Know if My CNC Laser is Focused?

CNC laser machines are used in various industries, including manufacturing, automotive, aerospace, and many others. These machines are capable of cutting and engraving a wide range of materials, including metal, wood, plastic, and more. However, it is crucial to ensure that the laser is focused correctly to achieve high-quality results. In this article, we will discuss how to know if your CNC laser is focused and the importance of having a focused laser.

What is a Focused Laser?

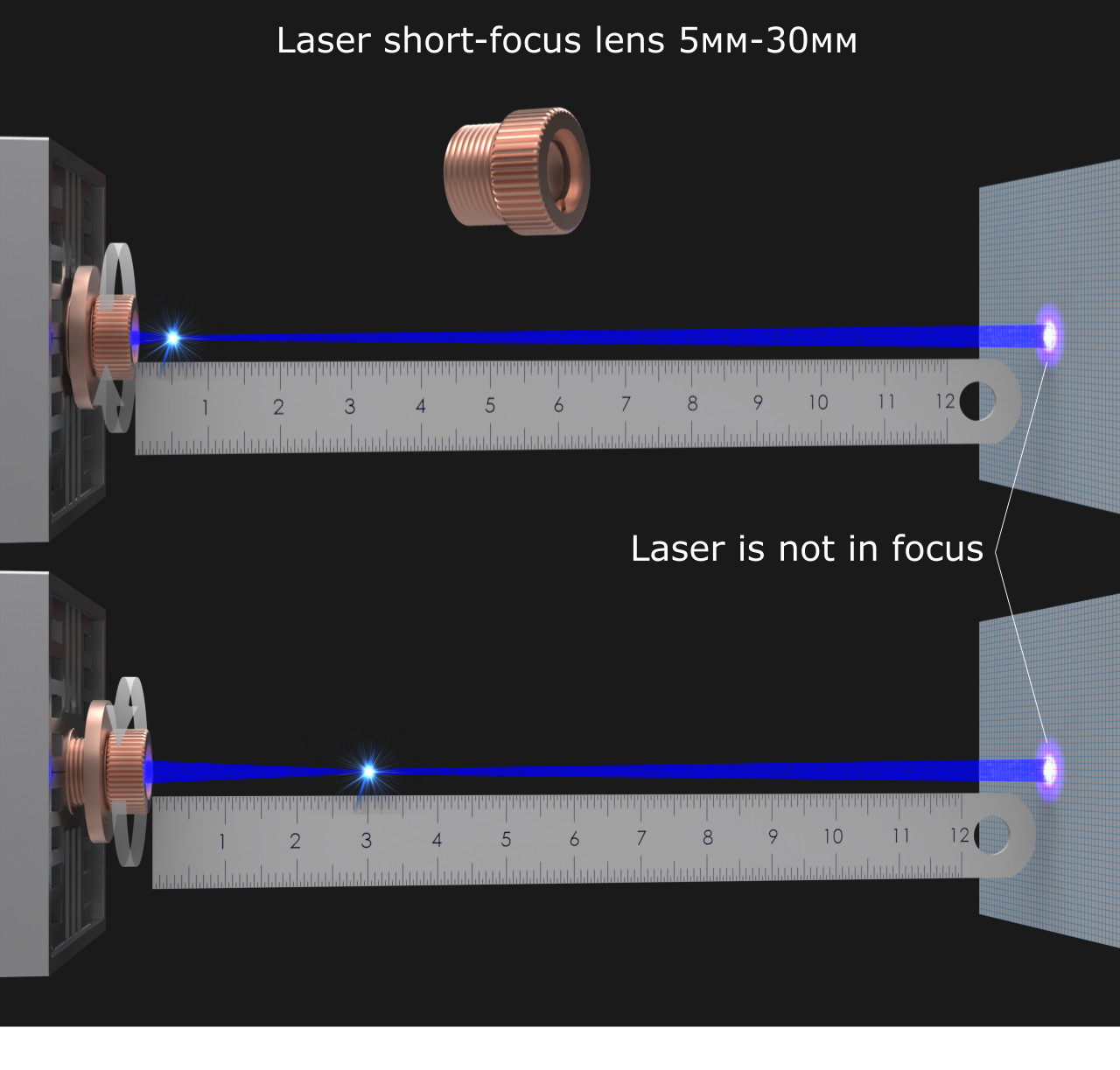

A focused laser beam is a concentrated beam of light that is used to cut or engrave materials. The laser beam is focused by a lens that adjusts the beam’s width and intensity to achieve the desired result. The focal point of the laser beam is the point at which the laser is most intense, and it is where the laser can cut through the material most effectively.

To ensure that the laser beam is focused correctly, you need to check the focal point of the laser beam regularly. If the laser beam is not focused, it will not cut or engrave materials correctly, resulting in poor-quality results.

How to Check if Your CNC Laser is Focused?

Checking the focus of your CNC laser is a straightforward process. Here are the steps to follow:

Step 1: Prepare Your Laser Machine

Before checking the focus of your CNC laser, you need to prepare your machine by following these steps:

- Turn on your laser machine and let it warm up for at least 10 minutes.

- Make sure that the lens is clean and free of debris.

- Set up your material and ensure that it is secured in place.

Step 2: Move the Laser Head to the Material

After preparing your machine, you need to move the laser head to the material you want to cut or engrave. Ensure that the laser head is at the correct distance from the material. The distance between the laser head and the material should be the same as the focal length of the lens.

Step 3: Run a Test Cut or Engrave

Run a test cut or engrave on the material to check the focus of the laser beam. If the laser beam is focused correctly, the cut or engraving should be clean and precise. If the laser beam is not focused, the cut or engraving will be blurry, and the edges will not be sharp.

Why is it Important to Have a Focused Laser?

Having a focused laser is essential for several reasons. Here are some of the benefits of having a focused laser:

1. High-Quality Results

A focused laser beam produces clean and sharp cuts and engravings, resulting in high-quality results.

2. Increased Productivity

A focused laser beam cuts or engraves materials quickly and efficiently, resulting in increased productivity.

3. Reduced Material Waste

A focused laser beam cuts or engraves materials precisely, resulting in reduced material waste.

4. Longer Lifespan of Your Machine

A focused laser beam reduces the wear and tear on your machine, resulting in a longer lifespan.

5. Cost Savings

Having a focused laser beam reduces material waste and increases productivity, resulting in cost savings.

Conclusion

Ensuring that your CNC laser is focused is crucial for achieving high-quality results and maximizing the lifespan of your machine. By following the steps outlined in this article, you can easily check the focus of your laser beam and enjoy the benefits of having a focused laser.

Frequently Asked Questions

In this section, we will answer some common questions related to CNC laser focus. If you are concerned about the focus of your CNC laser, this guide will provide you with some useful insights and answers.

How do I know if my CNC laser is focused?

The focus of a CNC laser is critical to the quality of the cuts and engravings it produces. A well-focused laser will produce sharp, precise cuts, while a poorly focused laser will produce blurry and distorted cuts. Here are a few ways to know if your CNC laser is focused:

Firstly, you can visually inspect the cuts and engravings produced by your CNC laser. If the lines are sharp and clear, the laser is likely well-focused. If the lines appear blurry or distorted, the laser may need to be refocused.

Secondly, you can use a focus gauge to measure the focus of your CNC laser. A focus gauge is a tool that helps you measure the distance between the laser nozzle and the workpiece. By using a focus gauge, you can ensure that your laser is focused correctly and producing the best results possible.

What is the optimal focus distance for a CNC laser?

The optimal focus distance for a CNC laser depends on a few factors, such as the thickness and material of the workpiece, the type of laser, and the power of the laser. In general, the optimal focus distance for a CO2 laser is between 2 to 5 mm, while fiber lasers have a smaller focus range of around 0.5 to 1.5 mm.

To determine the optimal focus distance for your CNC laser, you can consult the user manual or contact the manufacturer. Additionally, you can experiment with different focus distances and observe the results to determine what works best for your specific application.

What are the consequences of an incorrectly focused laser?

An incorrectly focused laser can have a significant impact on the quality of the cuts and engravings produced by your CNC machine. If the laser is not focused correctly, the cuts may be blurry, distorted, or incomplete. Additionally, an incorrectly focused laser may cause damage to the workpiece or the machine itself.

Furthermore, an incorrectly focused laser can result in a decrease in productivity and an increase in material waste. A well-focused laser produces efficient and precise cuts, while an incorrectly focused laser may require multiple passes or cause damage to the material, resulting in wasted time and resources.

How often should I check the focus of my CNC laser?

The frequency at which you should check the focus of your CNC laser depends on a few factors, such as the frequency of use and the type of materials you work with. In general, it is recommended to check the focus of your laser at least once a week if you use it frequently or work with a variety of materials.

You should also check the focus of your laser if you notice a decrease in the quality of the cuts or if you experience any issues with the machine. By regularly checking the focus of your CNC laser, you can ensure that it is producing the best results possible and minimize any potential issues or downtime.

How do I adjust the focus of my CNC laser?

The process of adjusting the focus of your CNC laser depends on the specific machine and type of laser you have. In general, you will need to adjust the distance between the laser nozzle and the workpiece to achieve the optimal focus.

To adjust the focus of your CNC laser, you can use a focus gauge or follow the instructions provided in the user manual. Some machines may have an automatic focus adjustment feature that simplifies the process.

In conclusion, ensuring that your CNC laser is focused is crucial for achieving accurate and high-quality results. There are several ways to determine whether your laser is focused, including checking the beam diameter, measuring the beam divergence, and performing a focus test using a material sample. By regularly checking and adjusting the focus of your CNC laser, you can ensure that your workpiece is cut or engraved with precision and efficiency.

Remember that a poorly focused laser can result in uneven cuts, charring or burning of the material, and decreased productivity. Don’t ignore the importance of maintaining the focus of your CNC laser and always take the necessary steps to ensure that it is properly aligned and calibrated. With a focused laser, you can achieve exceptional results and take your CNC laser cutting or engraving to the next level.

In summary, whether you are a beginner or an experienced CNC laser operator, understanding how to check and adjust the focus of your laser is essential. By following the guidelines outlined in this article, you can confidently determine whether your laser is focused and make the necessary adjustments to achieve the best results. Keep practicing and refining your skills, and you’ll soon be a pro at operating your CNC laser with precision and accuracy!

Request a quote today!

[contact-form-7 id="1578" title="Contact form"]

Please compress the file into a ZIP or RAR file before uploading. Alternatively, send through your RFQ by email.

enquires@unitymanufacture.com